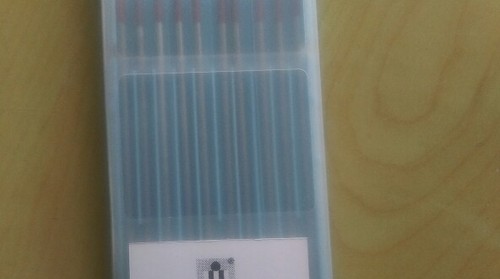

TIG Welding parts

TIG stands for tungsten inert gas and is technically called gas tungsten arc welding (GTAW). The process uses a non-consumable tungsten electrode that delivers the current to the welding arc. An inert gas, typically argon, protects and cools the tungsten and weld puddle. TIG Welding (GTAW) is a process that uses a non-consumable tungsten electrode

Enquiry NowTIG stands for tungsten inert gas and is technically called gas tungsten arc welding (GTAW). The process uses a non-consumable tungsten electrode that delivers the current to the welding arc. An inert gas, typically argon, protects and cools the tungsten and weld puddle.

TIG Welding (GTAW) is a process that uses a non-consumable tungsten electrode to produce a weld with or without filler material.

Different from tungsten electrodes in that they must be fed manually into the molten puddle by hand. The TIG filler rod must correctly match the material to weld, and the thickness of the material will determine the diameter of the rod.